Manufacturing Capabilities

Manufacturers rely on components and fasteners that strictly adhere to dimensional accuracy, down to the lead and pitch of screw threads. Utilizing precision gages and thread grinding services can verify that all fasteners used meet compliance requirements and fall within the necessary tolerances.

At Gage Assembly Co., we specialize in high-quality gages and thread grinding, so we can offer all of our clients access to highly precise products. As a member of the National Association of Manufacturers, we’ve provided threaded components for some of the world’s most demanding industries and can develop custom gages for projects based on unique customer designs and requirements. Learn more about our manufacturing capabilities and how we use these to provide high-quality standard and custom gage solutions for our customers across industries.

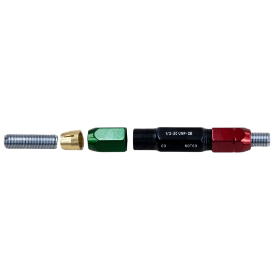

Precision Thread Plug Gages

Precision thread plug gages are measuring tools that can verify fastener and component dimensions as part of quality control and assembly processes. These gages are designed to measure the pitch diameter, the distance between threads along the length of a fastener.

The wrong screws can fail to mate properly with predrilled or pre-threaded components, making an assembly more susceptible to loosening, breakage, or poor performance. Using precision thread gages and measuring tools from Gage Assembly helps identify defects early in the process, ensuring accuracy in safety critical applications and reducing the need for costly rework or scrap.

At Gage Assembly, we can manufacture standard and custom thread gages that measure sizes ranging from 000-120 threads per inch, up to 15-½ inches in diameter. Types of precision thread gages we offer include:

Ring Gages

Ring gages are another type of thread measuring tool that operators can use to check external threads. Ring gages can be used to check low-volume and specialty fasteners as well as high-volume components to guarantee compliance with industry-specific requirements.

At Gage Assembly, we use high-performance, sturdy metals that retain stable dimensionality at varying temperatures and won’t wear down or deform. We also manufacture our thread ring gages with root relief or root clearance to ensure the gage provides proper contact and accurate measurements. The benefits of choosing ring gages with root clearance can include:

Advanced Inspection

Gage Assembly is an ISO 9001:2015 certified company, and we’re committed to ensuring product quality through consistent processes and advanced inspection capabilities. We use high-quality tool steel when manufacturing thread gages, and our routine inspections use advanced calibrated inspection equipment to assess final product accuracy and provide documentation on finished products.

We believe high-quality inspection services are an essential aspect of providing good service. We manufacture our gages for dimensional accuracy, consistency, and performance, so they can provide top-of-the-line inspection and quality control in our customers’ processes.

Custom Solutions

Along with standard thread plug gages and ring gages, Gage Assembly can manufacture gages for custom projects. Our specialty thread plug gages and thread ring gages have been used to check parts used in a range of applications and environments, including space exploration and satellite technology.

Some of our gage capabilities include the following:

- ACME

- ANPT

- British BSW

- BUTRESS

- DIN

- JIS

- Metric

- NH

- NPSM

- NPT

- UN

- UNM

- UNS

We also manufacture extra-length threads, pre-plate thread plugs and rings, solid rings, concentricity plugs and rings, left-hand gages, hard chrome gages, and much more. Special gages can be manufactured to your part or gage drawings as well.

Why Choose Gage Assembly?

Gage Assembly has been developing high-quality gages since 1953. In that time, we’ve served industrial companies by producing standard and custom thread gages for precision measuring and verification. Today, we maintain in-house CNC machining equipment in our Lincolnwood, Illinois, facility and can produce specialty gages and threads for most applications. Our company is committed to quality and integrity, and we’re a member of the National Association of Manufacturers. Our customers benefit from our custom capabilities, competitive pricing, and adherence to strict quality and compliance requirements.

Premium Manufacturing Services From Gage Assembly

By choosing gages from Gage Assembly, you can ensure better dimensional accuracy and performance from start to finish. Our cutting-edge manufacturing facility uses in-house CNC machining equipment and internal and external thread grinding machines. We also offer a hard chrome finish on all standard thread plug gages, and can apply this service for special gages. With customers in aerospace, automotive, defense, energy, and other major industries, we’ve maintained a reputation for integrity and reliability as we serve manufacturers across multiple sectors.

Contact us today to learn more about how we can help with your next project or request more product details.