Products

Gage Assembly offers an extensive range of precision gages manufactured to meet industry-specific needs. We use cutting-edge CNC thread grinding technology to create extremely accurate products in-house from our Lincolnwood, Illinois, facility. Whether you’re looking for a standard gage or one of our custom thread gage solutions, our team can meet your project’s needs.

Thread Plug Gages

Thread plug gages verify the pitch diameter and fit of threaded parts. We offer several types of thread plug gages, including taperlock, reversible, and trilock. Thread gage size capabilities run from 000-120 threads per inch to 15-½ inch diameter and one thread per inch.

Taperlock Thread Plug Gages

This type of thread gage is used to check the accuracy of internal threads. Its taperlock design ensures a secure fit, simplifying handling and reducing the chance of slippage during inspections. Taperlock thread plug gages are used in many industrial applications and come in a variety of sizes to produce consistently accurate measurements every time.

Reversible Thread Plug Gages

Reversible thread plug gages feature both GO and NO GO ends to quickly verify whether or not a threaded component adheres to its required specifications. These gages are precision-engineered to meet tight tolerance requirements and reliably deliver accurate measurements. Our reversible thread plug gages are manufactured from durable, high-quality graphitic tool steel.

Trilock Thread Plug Gages

Trilock thread plug gages maintain high precision in critical applications. These gages are built from durable materials like graphitic tool steel and hard chrome that can withstand intensive use while producing high-accuracy results. Trilock thread plug gages are used in demanding industries, like automotive and aerospace manufacturing.

Thread Ring Gages

Thread ring gages verify the accuracy of external threads to ensure threaded components fit securely. Our products are available in many sizes to accommodate a wide range of thread dimensions and are all produced using high-quality graphitic tool steel for long-term reliability, even under demanding industrial use.

STI (Helical Coil) Thread Plug Gages

Also known as helical coil thread plug gages, these gages are designed for screw thread inserts (STI). They check that the threaded holes adhere to the specifications needed for insert installation. Our STI thread plug gages are precision-made according to your application’s exact dimensions to guarantee a secure fit. These gages are essential for applications that require durable threaded connections to withstand high levels of stress.

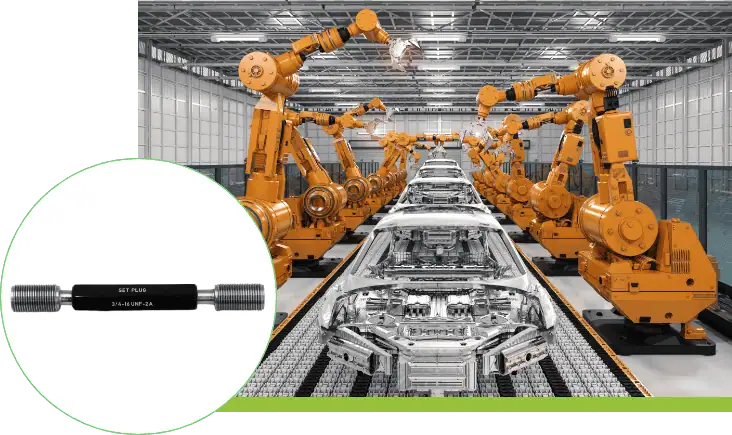

Set Plug Gages

Set plug gages verify the accuracy of thread ring gages , ensuring they have been manufactured according to specifications. They are available in a wide range of sizes to meet diverse application needs, including everything from small components to large industrial parts. Our precision-manufactured set plug gages provide the accurate measurements necessary to maintain quality control during manufacturing.

Plain Gages

Also known as a pin gage, or a cylindrical gage, a plain gage verifies the diameter of a bore hole. We offer several types of plain gages, including:

- Taperlock plain plug gages

- Reversible plain thread plug gages

- Trilock plain plug gages

- Master setting discs

Taperlock Plug Gages

A plain plug gage measures the dimensions of a part by entering or not entering the internal thread (inside the hole of a part as required). The Go end should engage and the Not Go (NoGo) end should not engage the part. This is known as fixed limit gaging.

Taperlock style (000 to 1.5 inches diameter sizes only): These gages have a tapered shank. They are firmly pressed into an aluminum handle that has a matched tapered hole. New gage members can be inserted into the existing handle.

Gage Assembly offers high quality taperlock plain plug gages.

Reversible Plain Plug Gages

Reversible plain plug gages feature GO and NO GO ends for fast and efficient hole sizing. These gages have been precision-engineered so that all holes adhere to the required specifications. Our products are made to last from durable materials that can easily withstand prolonged use. Reversible plain plug gages deliver simple, accurate results.

Trilock Plain Plug Gages

Trilock plain plug gages are essential for verifying accurate hole dimensions, especially in applications where exact precision is critical. Our products are constructed from quality, durable materials and designed for long-term use. With their high precision and reliability, trilock plain plug gages are indispensable for applications throughout the aerospace and automotive industries.

Master Setting Discs

Precision-manufactured master setting discs are used as reference standards for calibration. These products determine the accuracy of all other measurement tools. We offer many sizes for calibrating a wide range of instruments and gages.

Catalog Gages

No matter what your industry needs are, we have a solution for you. In addition to our plain and thread plug and ring gages, we also offer gages for verifying NPT, NPTF, ANPT, and NPSM thread dimensions.

NPT Thread Gages (National Pipe Taper)

NPT thread gages are precision tools designed to check that tapered threads can achieve a tight, leakproof seal. These gages are essential in many plumbing and hydraulic applications. Built from durable materials, they can withstand frequent use in the most demanding industries.

NPTF and ANPT Gages (National Pipe Taper Fuel and Aeronautical National Pipe Taper)

NPTF and ANTP gages are ideal for ensuring dry seal connections without leaks. With high-precision performance, they are used in applications where achieving a tight seal is critical. We offer multiple sizes of these gages to meet industry-diverse needs.

NPSM Thread Gages (National Pipe Straight Mechanical)

NPSM thread gages are designed for straight pipe threads. They offer highly accurate and reliable measurements to make sure all components fit securely. Our gages are constructed from durable materials for a long service life. NPSM thread gages verify that National Pipe Straight Mechanical thread dimensions are met in plumbing and mechanical applications.

Find the Right Precision-Manufactured Gages at Gage Assembly

At Gage Assembly, we’ve helped the world’s most demanding industries achieve unmatched accuracy for over 70 years. We pride ourselves on our extensive range of high-quality, American-made products at competitive prices. No matter what challenges your application involves, our team can help you find the right solution.

Explore our full range of product offerings by requesting a catalog, or contact us if you have any questions.